Introduction to Production Management

Production management means planning, organising, directing and controlling of production activities. Production is a scientific process which involves transformation of raw material (input) into desired product or service (output) by adding economic value. Production management deals with converting raw materials into finished goods or products.

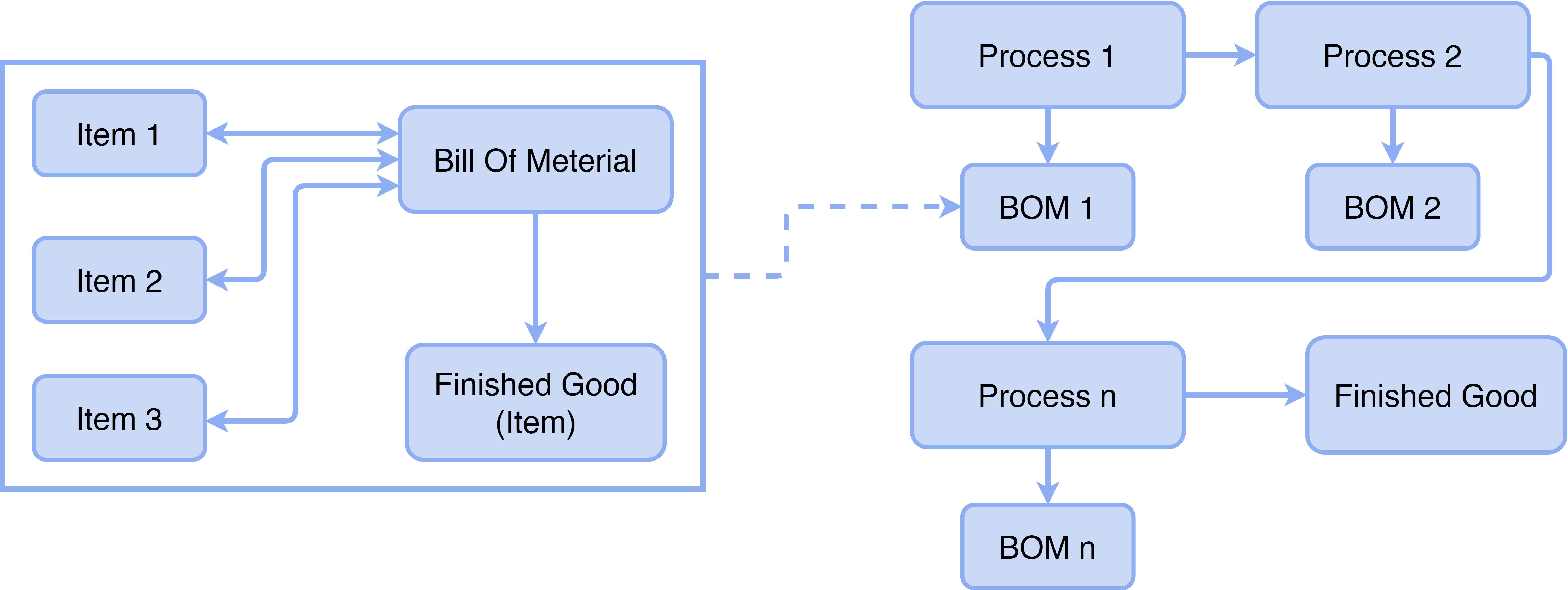

Production Management flow chart

Importance of Production Function and Production Management

Successful organizations have well defined and efficient production function and support function. Production function directly affects customer experience and there by future of organization itself.

Aim of production function is to add value to product or service which will create a strong and long lasting customer relationship or association. And this can be achieved by healthy and productive association between Marketing and Production people.

- Bill of Material

Bill of Material (BOM) is a base functionality of setting up production module of an ERP system. A manufactured item consists of components, which are used to build the product through production operation(s). The main use of BOM is to define product structure of a manufactured end item. Routing is another important base of production module, which defines the method of manufacturing.

Method or route to be followed for manufacturing a product is a prerequisite for setting up production module.

- Routing

Any manufacturing process goes through various phases of production and at each phase, components (either work in progress or purchased) are needed. BOM details components required at various phases or levels of operations.

Reporting.

Standard reports are available with rich parameters and options. With the help of easy-to-use options, Excel, PDF, text documents can be transferred easily to different environments. There are provision to get output of production orders, picking list etc.

Key Features.

- Base creation for production plans and production orders

- Production route management

- Configurable operation durations and timelines.

- Consecutive Loading / Parallel Processing

- Production formulas and routes specific to enterprises.